Delving into the world of vinyl siding labor, this guide aims to provide a detailed overview of the process, costs, timeframe, and techniques involved. Whether you’re a DIY enthusiast or considering hiring professionals, this information will help you make informed decisions.

Exploring the intricacies of vinyl siding labor can shed light on the tools, tasks, and factors that play a crucial role in the installation process.

Vinyl Siding Labor Overview

Installing vinyl siding involves covering the exterior walls of a building with vinyl panels to provide protection and improve aesthetics. It is a popular choice for homeowners due to its durability, low maintenance requirements, and variety of colors and styles.

Typical Tasks in Vinyl Siding Labor

- Preparing the surface: This involves cleaning the walls, removing any existing siding, and repairing any damage.

- Measuring and cutting: Accurately measuring the dimensions of the walls and cutting the vinyl panels to fit properly.

- Installing the panels: Attaching the vinyl panels to the walls using nails or clips, ensuring they are level and securely fastened.

- Adding finishing touches: Installing corner pieces, J-channels, and trim to complete the look and ensure proper fit.

- Cleaning up: Removing any debris and ensuring the work area is tidy.

Tools and Equipment Needed for Vinyl Siding Installation

- Vinyl siding panels

- Nails or clips for fastening

- Tape measure

- Utility knife or vinyl cutter

- Ladder or scaffolding

- Hammer or nail gun

- Level

- Caulk and caulking gun

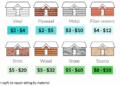

Vinyl Siding Labor Cost Factors

The cost of vinyl siding labor can vary based on several factors that influence the overall pricing. Understanding these factors is essential when considering a vinyl siding installation project.

Factors Influencing Vinyl Siding Labor Costs

- The size of the house: Larger houses require more materials and labor, which can increase the overall cost of the project.

- The shape of the house: Houses with complex shapes or multiple stories may require additional time and expertise to install the siding properly, impacting labor costs.

- Location: Labor costs can vary depending on the geographical location of the property, with urban areas typically having higher labor rates than rural areas.

- Accessibility: Houses that are difficult to access or require special equipment for installation may incur higher labor costs.

- Quality of materials: Higher quality vinyl siding materials may require more skilled labor for installation, potentially increasing the labor costs.

DIY vs. Hiring Professionals

Installing vinyl siding yourself can save money on labor costs, but it requires significant time, effort, and skill. Hiring professionals ensures a faster and more precise installation, but it comes with higher labor costs. Consider the trade-offs between cost savings and expertise when deciding between a DIY project or hiring professionals.

Impact of House Size and Shape on Labor Costs

The size and shape of a house directly impact labor costs for vinyl siding installation. Larger houses with complex shapes or multiple stories will require more time and labor to complete the project, leading to higher overall costs. It is essential to consider these factors when budgeting for a vinyl siding installation to ensure an accurate estimate of labor expenses.

Vinyl Siding Labor Timeframe

Installing vinyl siding typically takes about 2-3 weeks to complete for an average-sized home. This timeframe includes the preparation work, such as removing old siding, and the actual installation of the new vinyl siding.

Weather Conditions Impact

Weather conditions play a significant role in the vinyl siding labor timeframe. Rainy or windy weather can delay the installation process as it is not safe or feasible to work in such conditions. Extreme heat or cold can also affect the materials and slow down the installation process.

It is essential to schedule the installation during a period of stable weather to ensure timely completion.

Importance of Proper Planning

Proper planning is crucial to ensure the timely completion of the vinyl siding installation. This includes ordering materials in advance, scheduling the labor team efficiently, and accounting for any potential weather delays. A well-thought-out plan will help streamline the installation process and prevent any unnecessary setbacks, ultimately ensuring that the project is completed within the estimated timeframe.

Vinyl Siding Labor Techniques

Installing vinyl siding requires specific techniques to ensure a successful outcome. Here are some best practices to consider when cutting and installing vinyl siding, along with the importance of proper insulation and moisture barriers in the labor process, as well as common mistakes to avoid.

Best Practices for Cutting and Installing Vinyl Siding

- Measure twice, cut once: Accurate measurements are crucial to ensure that the vinyl siding fits properly.

- Use the right tools: Invest in quality siding tools such as a vinyl siding cutter, snap lock punch, and zip tool for efficient installation.

- Start from the bottom up: Begin installing vinyl siding from the bottom and work your way up to prevent water infiltration.

- Overlap correctly: Make sure to overlap the siding panels correctly to prevent gaps and ensure a seamless appearance.

Importance of Proper Insulation and Moisture Barriers

Proper insulation and moisture barriers play a crucial role in vinyl siding installation to protect the home from moisture damage and improve energy efficiency.

- Install house wrap: Use a weather-resistant barrier such as house wrap underneath the vinyl siding to prevent water infiltration and enhance insulation.

- Ensure ventilation: Proper ventilation behind the siding helps prevent moisture buildup and mold growth, prolonging the lifespan of the siding.

- Seal joints and seams: Apply sealant to all joints and seams to create a watertight barrier and prevent air leaks.

Common Mistakes to Avoid During Vinyl Siding Installation

- Ignoring manufacturer guidelines: Always follow the manufacturer’s instructions for proper installation to avoid costly mistakes.

- Improper nailing: Use the correct nails and spacing to secure the siding properly and prevent buckling or warping.

- Skipping insulation: Failure to install proper insulation can lead to energy loss and moisture issues, compromising the siding’s performance.

- Not addressing underlying issues: Before installing vinyl siding, ensure that any existing structural issues or water damage are addressed to prevent future problems.

Outcome Summary

In conclusion, mastering vinyl siding labor involves understanding the nuances of installation, cost considerations, timeframes, and best practices. By implementing proper planning and techniques, you can achieve a seamless siding transformation for your home.

Top FAQs

What tools are needed for vinyl siding installation?

Tools required include a hammer, utility knife, tape measure, chalk line, and zip tool for removing siding panels.

How does weather impact the timeframe for vinyl siding labor?

Extreme weather conditions like rain or high winds can delay the installation process, affecting the overall timeline.

What are common mistakes to avoid during vinyl siding installation?

Avoid improper nailing, incorrect panel overlap, and inadequate insulation as these can lead to issues down the line.